For bad vis, like 6ft, and holes or shooting inside structure I'd like to use a Mares Cyrano 700. It's a 70cm air gun with a 7mm single flopper shaft. I rigged it with two wraps of stainless steel cable so a big fish can't cut the line over sharp metal structure. It's hard to beat a pneumatic for short range punching power and the absence of bands makes it very maneuverable in tight quarters. One disadvantage is that it's nose heavy and if I carry it in ready to shoot position, which one must do in poor viz, my hand and forearm get tired. One further mod I need to do is to add some kind of form fitting flotation to the front of the barrel.

Removed the safety and ground down the trigger which created a nice clean hole for attachment of the float line to the mono double loop. Took off the handle and wrapped tape around the handle stud to eliminate play in the handle.

Ground down and reshaped the loader to fit properly into the handle. The big trick was positioning a metal receptacle in the loader because otherwise the spear point gets stuck and costs a few seconds to remove. The ready made loaders that come with this metal cup are always too big to fit in the handle. I made the cup from a piece of 8mm shaft by using different size drill bits to create a cone shape. It is held tightly inside the plastic loader with epoxy. Works very well.

I wanted to see how well I could work the plastic. I ground down the sights and using sanding and Tin Man's steel wool method got the plastic looking almost original.

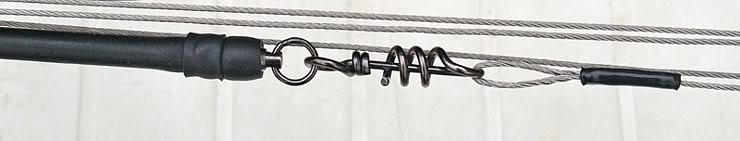

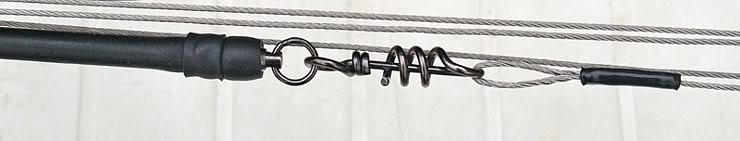

Drilled a hole and put a stainless rod through it and bent it to form a retainer for the flopper. A notch on the flopper accepts this retainer and stays put nicely. In holes many times a fish will get skewered in strange angles and the shaft gets difficult to remove. With this feature its slides right back out the way it came. The SS cable is braided and crimped.

The original line anchor is also theoretically supposed to hold the shaft when the gun is not in use. This doesn't function well as the shaft is not held tightly at all. Also the resulting line anchoring point is weak. I ground away the shaft retainer and drilled a hole as the new attachment point for the shooting line. I integrated a bungee into the hole. The bungee eliminates the need for a spring between the sliding line anchor on the shaft and the retaining ring.

The bungee has the stronger and easier to disconnect pigs tail snap and swivel combination. The cable is braided and crimped.

This is what a 20lb cuda did to the inferior conventional 400lb :rolleyes1: snap after wrapping the cable around structure.

Since the above pics were taken I found another alternative to the sliding plastic line anchor and ring. This little sliding line anchor does the job of both and makes the spear more streamlined. It fits perfectly into the muzzle the same way the ring did keeping the shaft nice and centered without play.

The piston adapter on the butt of the spear is ground down for a looser fit into the piston. This reduces the loss of power when the shaft leaves the piston. It also allows me to remove the spear from the gun while it's still in loaded condition. Last I changed the line release to the right to be consistent with my band guns and allow wrapping of the shooting line the same way; holding the gun with the left hand and wrapping with the right.

All I'm missing is the flotation device I previously mentioned. If someone sources one please let me know.