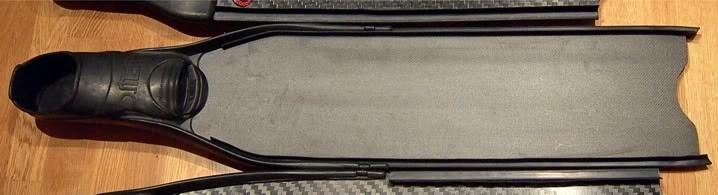

Some of this will be pretty basic, but I'm often reminded how many guys don't understand rails. There are two kinds of rails; water channeling, and tendon rails.

Water channeling rails

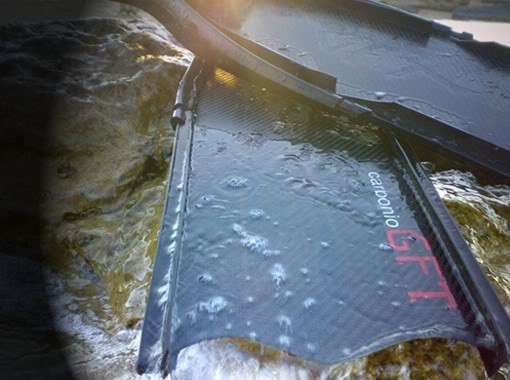

Water channeling rails are used to channel water down the blade, they eliminate the fin slipping off the water effect during the down stroke. This can be felt with many plastic fins which usually lack water channeling rails, and with some fiberglass and carbon blades where the manufacturer cut corners and didn't install good rails. Watch the beginning of this video of Sheri Daye using DiveR fins, notice the erratic movement of the fins on the descent. This is partially due to the DiveR being longer than the conventional 90cm, and is exaggerated because they lack water channeling rails, the fins become harder to control.

[VIMEO]13734159[/VIMEO]

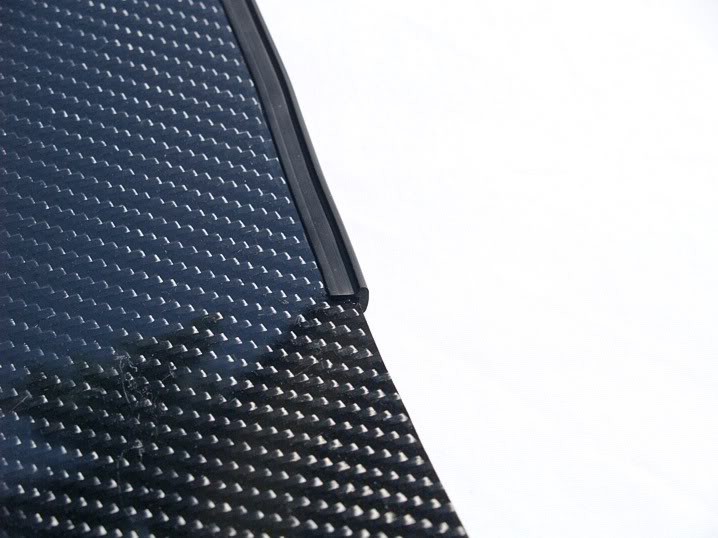

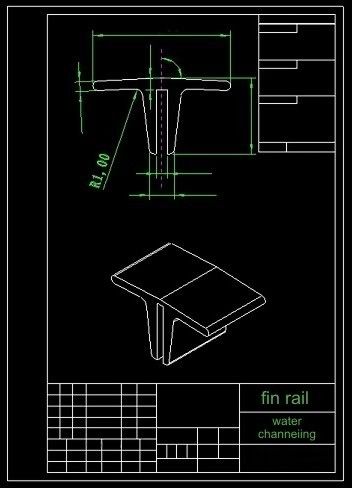

Ideally the water channeling rails start where the footpocket tendons end and continue all the way to the front edge of the blade. The height of the rails should be about 1.5cm/a little over .5". The grade of rubber of the water channeling rails should be soft enough that they don't interfere with the flexing of the blade, but stiff enough to maintain a straight profile. Another function of these rails is to protect the side edges of the blade against impact, the edge is where fiber fins are most sensitive.

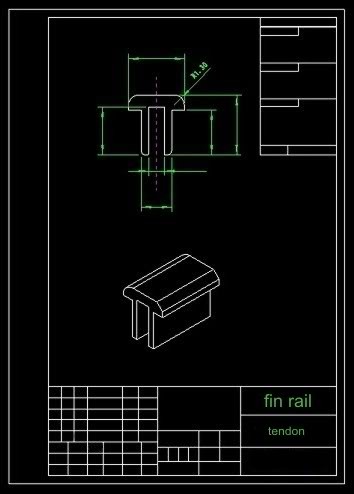

Here is the schematic for the Speardiver water channeling rails.

There has been little variation on the concept of water channeling rails. C4 came out with something they call the flap. Just as the name suggest it's a piece of loose rubber in addition to the normal rail height, that flaps around. I'm not sure what their reasoning for it is, but from what I hear people that get these fins end up cutting that part of the rail off. I never tried this flap but I miss it on my fins like I miss it on my ****. See the behavior of the rails when the blade is flexed, doesn't look efficient for water channeling.

EDIT - I found out the flap name is in reference to the shape of the front edge of the C4 not the rail flap.