Aaack! :@ Blasphemy!

If a device with no moving parts whose sole purpose is to sit on a rubber belt and be heavy can be improved, then so can anything else. .

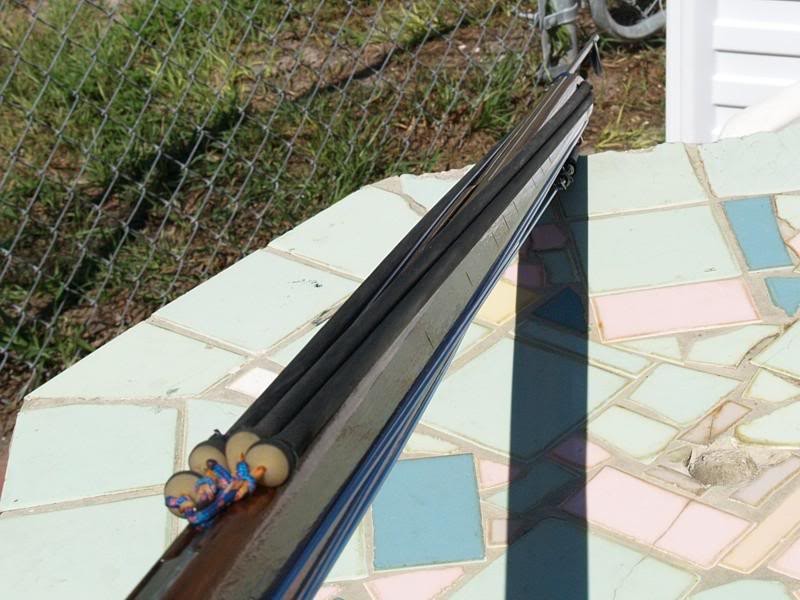

I thought that weight belts had reached their peak back in the eigthies!! :rolleyes1: Yet there are some really crazy people out there who actually managed to improve them :crazy: ![]()